PRODUCTS

Jinyuan Mining Machinery

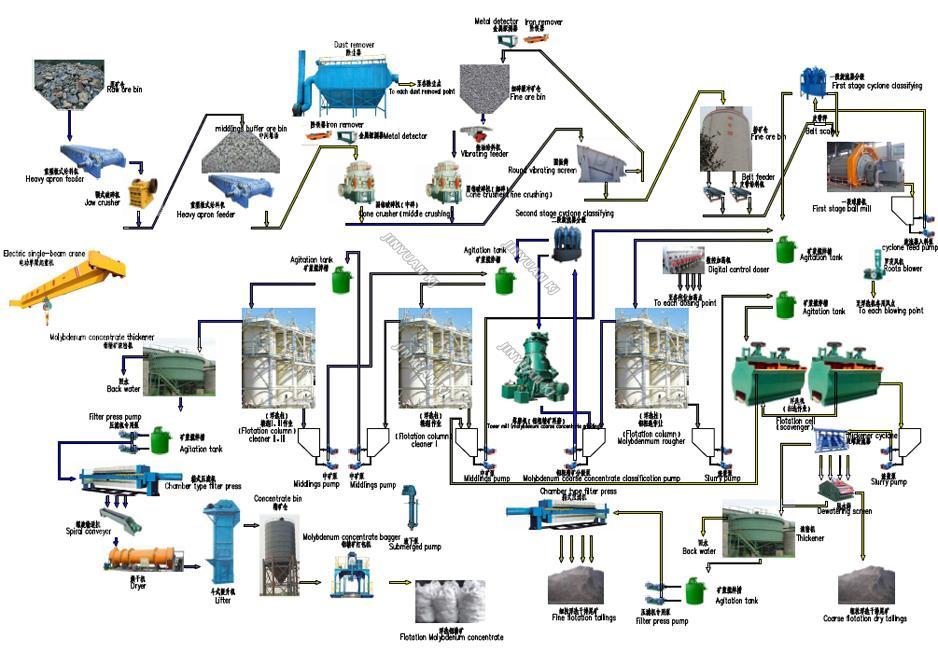

Molybdenum ore processing technical process

Keyword:

Mining Machinery

Category:

E-mail:yantaijinyuan@vip.163.com

- Details

- Models

-

- Commodity name: Molybdenum ore processing technical process

- Commodity ID: 1133883377996943360

Technical process introductionMolybdenum ore processing method is mainly flotation, recovered molybdenum minerals is molybdenite. Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, molybdenum concentrate will be re-processed by chemical dressing.Molybdenite has good natural flotability. However, flotability decreases when the mineral is overgrinding. Although a certain amount of collector such as xanthate is added at this time, which is beneficial to the recovery of molybdenite, the new slime generated by overgrinding affects the flotation effect. Therefore, the separation of molybdenite should avoid and prevent overgrinding. In the production, segmented grinding and multi-segment separation process should be adopted to gradually achieve the separation of monomer and ensure the high recovery rate of molybdenum concentrate.Technical processMolybdenum ore crushing generally adopts process of three-stage closed-circuit, the final product size of crushing is 12 ~ 15 mm. Usually use ball mill or rod mill for grinding. Preferred flotation method is adopted for flotation. Rougher flotation produces molybdenum concentrate, and recover associated minerals from rougher and scavenger flotation tailings or abandon tailings. Molybdenum concentrate is obtained after second or third stage re-grinding and Four ore five times cleaner flotation.In order to ensure the quality of molybdenum concentrate, the heavy metal minerals such as copper, lead and iron contained in molybdenum concentrate, calcium oxide and carbonaceous minerals need to be further separated.Process flow diagram

Related Products

Product Consultation